ASEV Poster: Treatment of Smoke Impacted Wines Using a Molecularly Imprinted Polymer Improves Sensory Outcomes

In June 2023 amaea, in conjunction with Jackson Family Wines, presented a technical poster to the American Society for Enology and Viticulture (ASEV) in Napa. The poster showcased how the treatment of smoke impacted wines using amaea’s molecularly imprinted polymers resulted in improved sensory outcomes and the long-term retention of those outcomes.

Authors:

Caroline Merrell, Torey Arvik and Sami Young- Jackson Family Wines, Sonoma, CA, USA

Sylvia Baars and Aaron Low - amaea, Hamilton, NZ

Introduction

Smoke exposure has had a devastating impact on the wine industry in recent years. In 2020 alone, it is estimated that wildfires cost the US wine industry $3.7 billion in lost revenue, wine inventory, grapes, and property.

Remediation of smoke impacted wines presents a significant challenge to winemakers, as currently available treatments can strip desirable attributes of a wine, including mouthfeel. Molecularly imprinted polymers (MIPs) present a unique treatment opportunity as they specifically bind compounds by molecular structure, leading to a more targeted compound removal. MIPs are manufactured to have specific capture cavities for a given compound or group of compounds.

The goal of this study was to test the chemical and sensory outcomes after treating wines with a volatile phenol removal MIP.

Materials and Methods

Five 2020 smoke impacted wines (three Napa County Cabernet Sauvignons and two Sonoma County Pinot noirs) were selected for treatment. All wines were naturally smoke impacted from fires throughout the growing season.

Wines were first treated using a bench-scale column containing 20g MIP (amaea VPx) in order to determine the preferred treatment rates by wine. MIP treatment is customizable by dose rate, flow rate, and number of passes.

During pilot-scale treatment, wine was pumped from one barrel, through a stainless-steel column containing 5 kg of MIPs, into a clean barrel. After treatment was complete, the MIPs were rinsed with water, then cleaned with 85% ethanol to remove the volatile phenols. Water was run through the column again before treating subsequent wines. Wine treatment rates varied in order to test the impact on volatile phenol removal (Table 1).

Smoke marker compounds were evaluated by headspace SPME-GC-MS-MS using a DVB/CAR/PDMS fiber (Supelco) and a Stabilwax column (Restek). Sensory analysis was completed by a panel of eleven winemakers approximately 45 days after treatment and again, one year after treatment. Wines were blindly evaluated using descriptive analysis (unanchored 10cm line scale, converted to a 0-100 rating).

Statistical analysis was performed using XLSTAT (analysis of variance, Fisher’s LSD p<0.05).

Table 1: Treatment Dose and Flow Rates by Wine Type

Figure 1: MIP Treatment Process

Sensory Results

MIP treatment significantly improved overall wine quality scores in three of the five wines (Napa CS 3, Sonoma PN 1 & 2; data not shown). In those wines, smoke aroma was significantly decreased while fruit aroma, flavor, and body were not significantly different from the control (Figure 2). The wines (Napa CS 1 & 2) where treatment was less successful at improving wine quality both started with a lower smoke impact (Table 2).

Figure 2: Sensory analysis of Napa CS 3 (A) and Sonoma PN 2 (B) approximately 45 days after treatment indicated a significant reduction in smoke aroma (* indicates significance at p<0.05)

“Molecularly imprinted polymers effectively reduce smoke aroma and flavor from impacted wines while retaining fruit character and body.”

Analytical Results

At the bench scale, MIP treatment reduced volatile phenol concentration by up to 71±2%. Lower treatment rates were selected at the pilot scale, since wines were only moderately smoke impacted. At the pilot scale, MIP treatment reduced volatile phenol concentration by 33-41% (Table 2).

Depending on the wine and treatment rate, MIP treatment also reduced thiophenol concentration by up to 30%, thiocresol concentration up to 68%, benzyl mercaptan concentration up to 100%, and thioanisole concentration up to 17%. Color and tannin loss ranged from 4-11% with treatment.

Table 2: Analysis of volatile phenol concentrations in control and MIP treated wines. Free cresol is represented as a sum of o-, m-, and p-cresol.

Changes One Year After Treatment

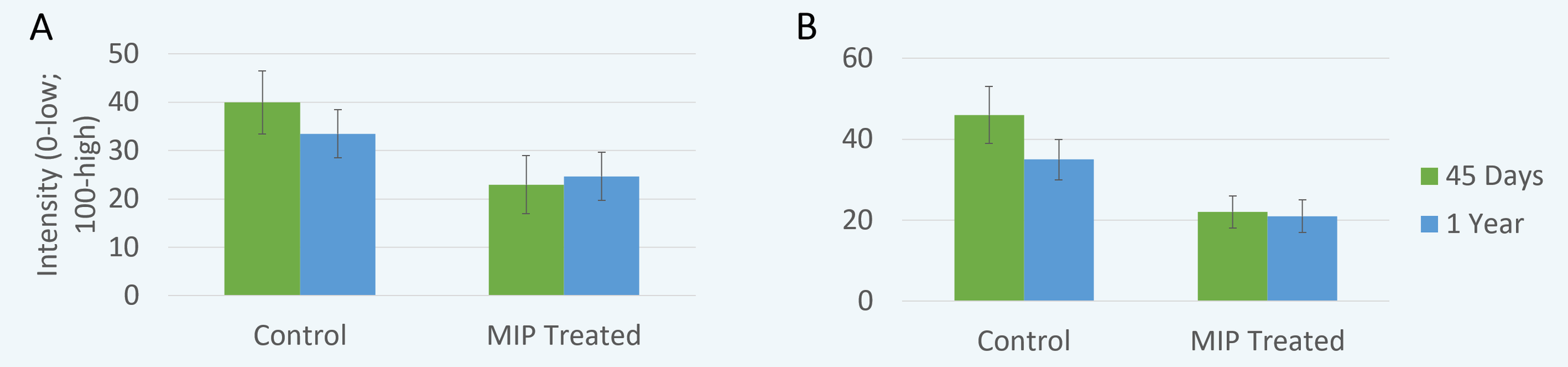

Wines were analyzed again one year after treatment. The concentration of free smoke marker compounds did not increase over time (data not shown). Sensory analysis was also performed after one year. Smoke aroma did not return in treated wines after 1 year (Figures 3, 4).

Figure 3: Sensory analysis of Napa CS 3 (A) and Sonoma PN 2 (B) approximately 1 year after treatment showed similar outcomes to sensory analysis performed 45 days after treatment (* indicates significance at p<0.05).

Figure 4: Smoke aroma intensity ratings of Napa CS 3 (A) and Sonoma PN 2 (B) indicate no significant increase in smoke aroma after 1 year.

Conclusions

Treatment with a volatile phenol MIP significantly reduced the concentration of smoke marker compounds in treated wines. Treatment also significantly reduced smoke aroma and flavor in select wines.

Acknowledgements: We thank members of the Jackson Family Wines winemaking team for identifying suitable wines for this trial, providing helpful insights, and participating in sensory analysis.